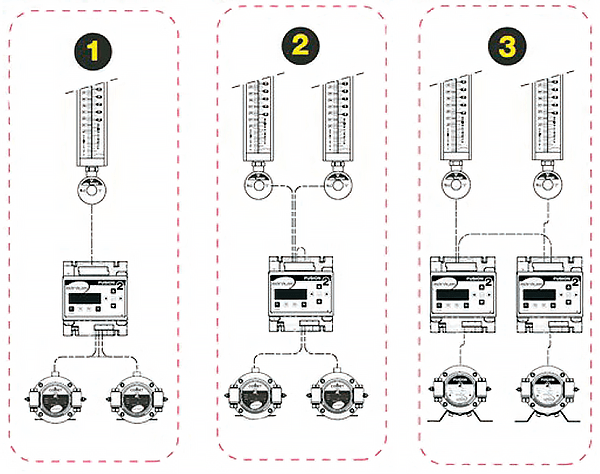

LEVEL 1

Two pumps are connected to a single controller, and both operate simultaneously. If one pump loses efficiency as noted by the InSight Smart Sight Glass, both motors increase rpm to compensate.

LEVEL 2

Two pumps are connected to a single controller, each using an independent InSight Smart Sight Glass. Only one pump runs at a time. If the operating pump's efficiency falls out of specification that pump stops and the redundant pump starts.

LEVEL 3

Two pumps are tied into two controllers each with its own InSight. Only one pump runs at a time. If the operating pump's efficiency falls out of specification that system stops and the second system starts.