The Fusion2TM is Sirius' smart

solution to chemical injection, pump

control in applications requiring a

motor less than ½ horsepower.

The controller has been designed to work with both sensored BLDC

and brushed motor/pump applications. Anywhere that you desire to:

have ultimate control

of your injection rates

communicate through

SCADA, or

simplify calibration

of the Fusion2TM

The Fusion2TM Intelligent Calibration is an in-situ test; thus, accounting for intake head, viscosity, and injection pressure. The Fusion2TMlearns what the operator is trying to achieve during calibration and performs the necessary calibration calculations so the operator does not have to. Visual Rate Feedback eliminates the guess work with setting rates.

For those customers who use both DC and AC power supplies we have made it even easier. The FUSIONTM controller operates on both power supplies making it seamless for operators. In addition, pumps can be moved around the field providing additional versatility to the system. An on board MPPT solar charger provides first in class power for tough solar applications.

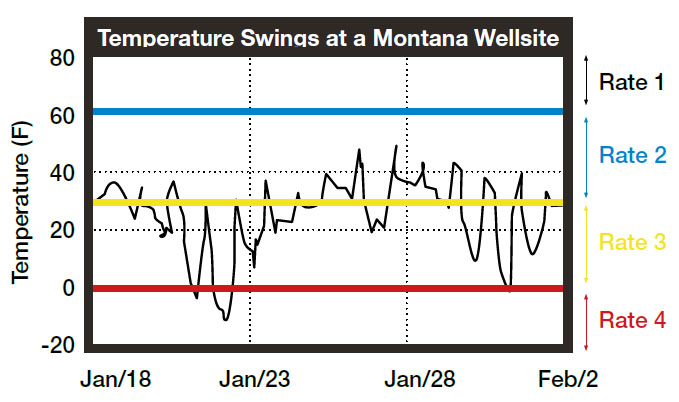

Conserve methanol using 4-zone temperature control. Flow rates automatically adapt to changing temperatures; saving chemical on warmer days while preventing freeze ups on cold winter nights.

Configure the controller for proportional rate control using an external sensor, or use multiple sensor inputs for even more advanced control. Fusion2 can be easily configured for the common equations such as Hammerschmidt or Gas Gravity methods.

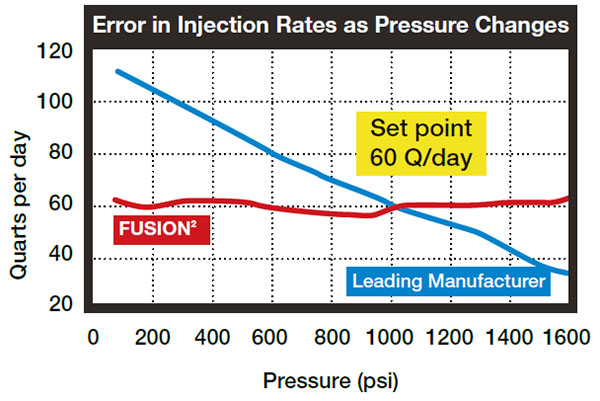

VARYING PROCESS PRESSURE CAN SIGNIFICANTLY AFFECT THE ACCURACY OF CHEMICAL INJECTED

Fusion2 compensates for process pressure fluctuations using patented pressure sensing technology.

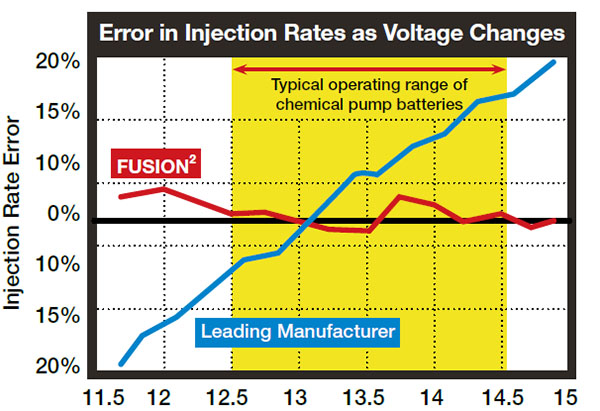

VOLTAGE FLUCTUATIONS AFFECT INJECTION RATE

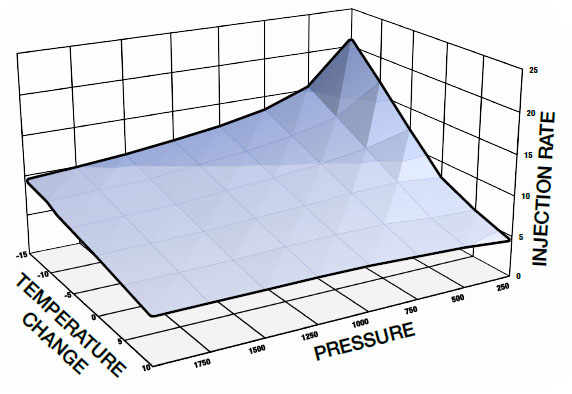

Solar powered pumps experience day/night voltage swings as well as longer term fluctuations from changing seasons, weather and cloud cover.

For most pumps, this voltage variation can generate injection rate errors exceeding 25%. Fusion2 maintains a constant injection rate using the patented voltage compensation feature.