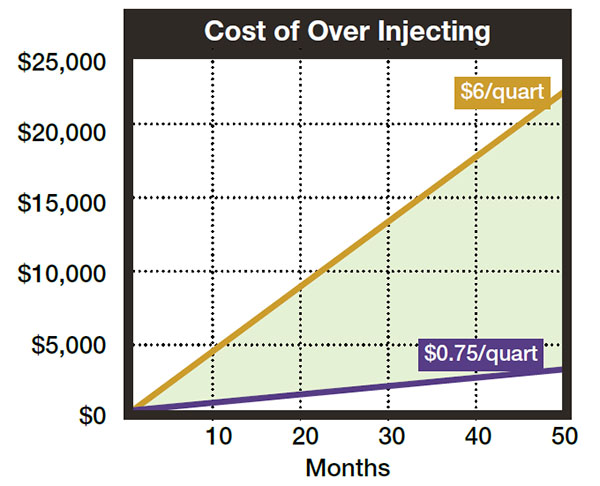

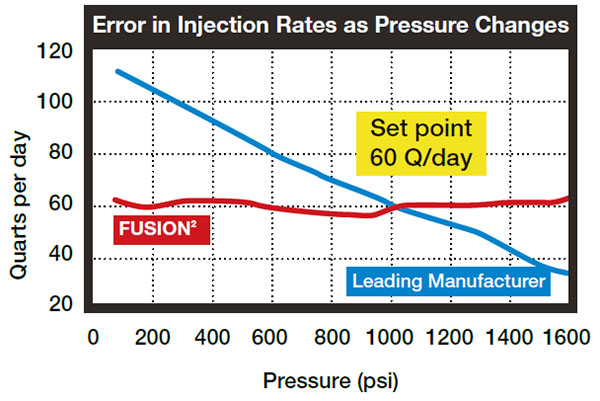

Inaccurate pumps force operators to over-inject

by an estimated 20% to ensure that minimum,

safe injection rates are met.

Using Fusion2 provides operators with the

accuracy required to allow operators to confidently

dial-back rates to inject only what is required.

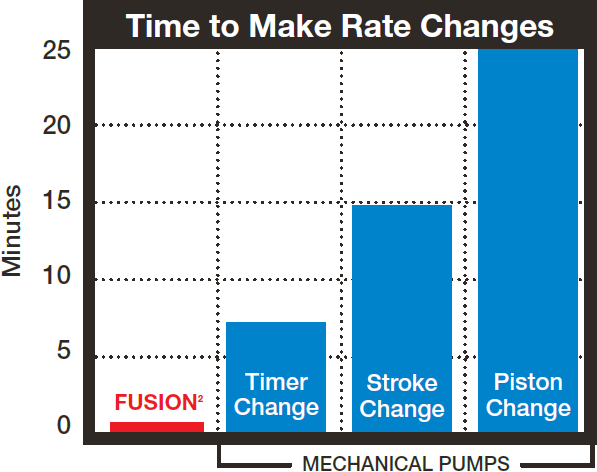

SINGLE BUTTON rate change with NO MECHANICAL ADJUSTMENTS

SELF-GUIDED PUMP CALIBRATION with NO CHARTS OR TABLES

Unique dual-seal technology overcomes the many shortcomings of adjustable packing designs. Maintenance is greatly reduced and chemical capability improved.

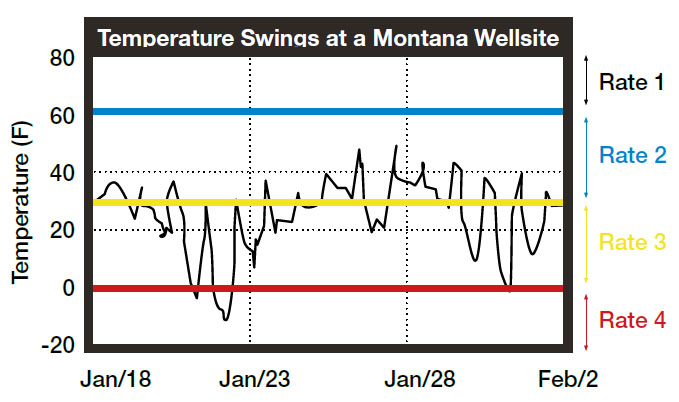

Conserve methanol using 4-zone temperature control. Flow rates automatically adapt to changing temperatures; saving chemical on warmer days while preventing freeze ups on cold winter nights.

Configure the controller for proportional rate control using an external sensor, or use multiple sensor inputs for even more advanced control. Fusion2 can be easily configured for the common equations such as Hammerschmidt or Gas Gravity methods.

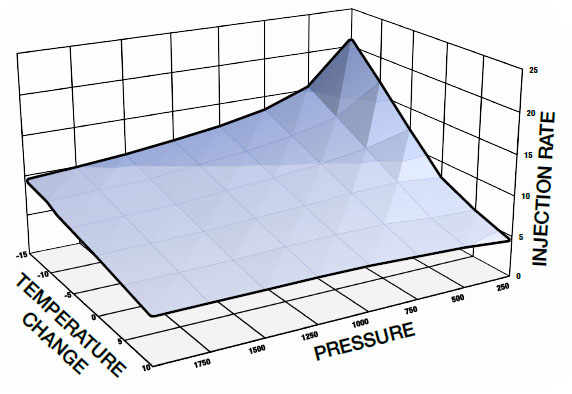

VARYING PROCESS PRESSURE CAN SIGNIFICANTLY AFFECT THE ACCURACY OF CHEMICAL INJECTED

Fusion2 compensates for process pressure fluctuations using patented pressure sensing technology.

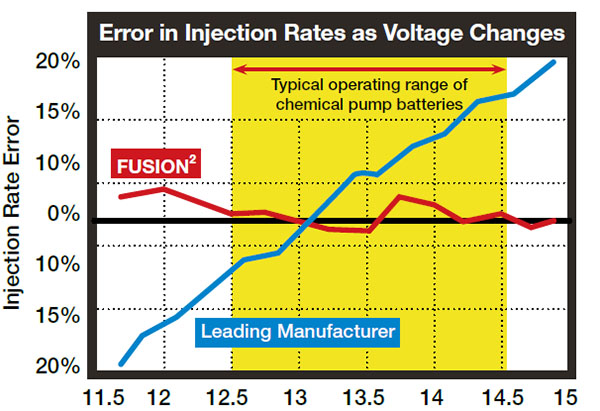

VOLTAGE FLUCTUATIONS AFFECT INJECTION RATE

Solar powered pumps experience day/night voltage swings as well as longer term fluctuations from changing seasons, weather and cloud cover.

For most pumps, this voltage variation can generate injection rate errors exceeding 25%. Fusion2 maintains a constant

injection rate using the patented voltage compensation feature.